Acoustic KN KW2201-16

Acoustic KN is a small company, specialized in repair and

production of limited quantities customized loudspeaker drivers.

KN stands for Krassy Nedelchev - an experienced audio engineer,

formerly worked for BMS company.

This is the person I trusted for the construction and production of a

bass driver, that embodies my concept for a good low-frequency

reproduction. My idea was to bring together the advantages of the

professional and h-fi cone drivers as far as it is possible.

The purpose of this driver is to be used as a bass unit in a compact

yet powerful multy-way system. The desired impedance of the acoustic

system was 8Ω using two bass units, that's why the impedance of each

one was planned to be 16Ω .

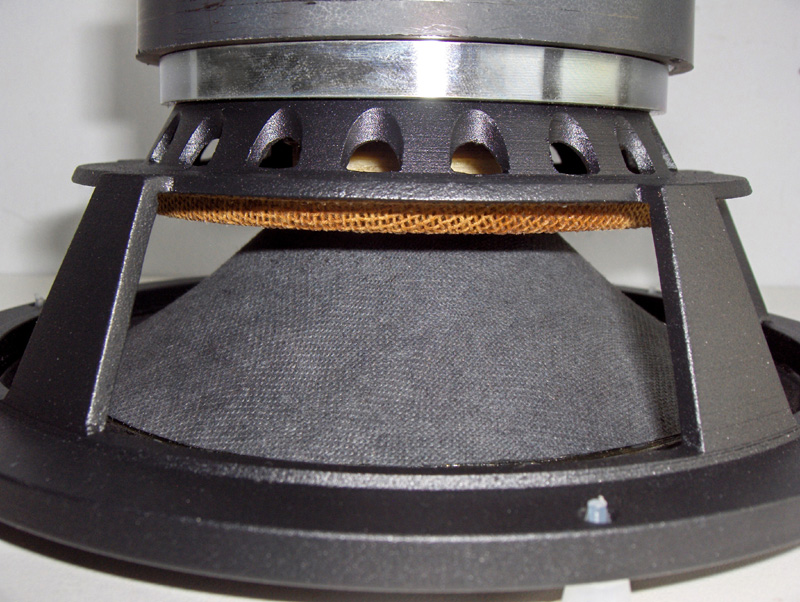

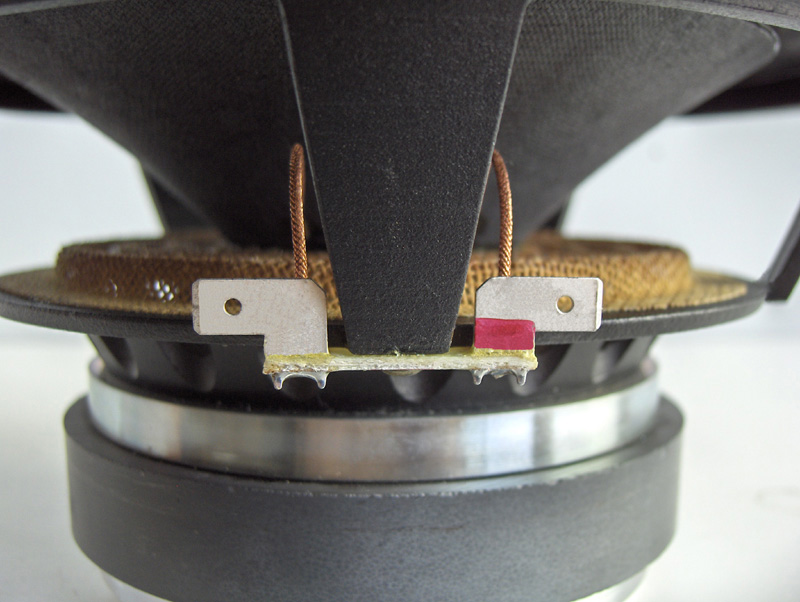

All of the parts this driver consists, except the cone, were

designed, constructed and produced by Acoustic KN.

The cone is paper and is enforced by carbon fibers.

The chassis is casted of aluminum alloy and then

precisely milled. The constructions is light, but very rigid,

with vented area behind the spider.

The two-inch diameter voice coil former was made of fiber glass

and high-temperature composite.

The strong magnet system delivers an excellent control of the

whole driver - the BL factor is about 15 Tm. In addition the

magnet system is vented too, allowing an extra cooling the voice

coil.

The close look of the spider shows, that the textile nest looks

a bit coarse. The vents in it allow the free air flow, when the

excursion of the cone is significant. The spider is coated

with the special unguent, that fixes its mechanical properties,

allowing almost everlasting consistence of the T/S parameters.

In fact this driver does not require any break-in. It passed one

week treatment with 6V sweep sine signal without changing the

T/S parameters more, than 1-2%.

Unlike the tough spider, the cone suspension is made of soft

rubber with a big acoustic losses, which terminates very well

the standing ways and allows a smooth and uncommitted movement of

the cone. T

The result is very low harmonic distortion at any

level of power.

My Measurements

| Driver Properties | Thiele - Small Parameters | ||||

|---|---|---|---|---|---|

| Chassis material | Die Cast Aluminum Alloy | Parameter | Measured | Datasheet | |

| Membrane material | Paper | Fs | 31 Hz | N/A | |

| Magnet System | Ferrite | Re | 11.9 Ω | N/A | |

| Surround | Rubber | Qms | 7.9 | N/A | |

| Voice Coil Diameter | 50 mm | Qes | 0.37 | N/A | |

| Nominal Impedance | 16 Ω | Qts | 0.35 | N/A | |

| Sensitivity | 90 dB/W/m | Vas | 40 ltr | N/A | |

| Rated Power | 90W | Le | 1.4 mH | N/A | |

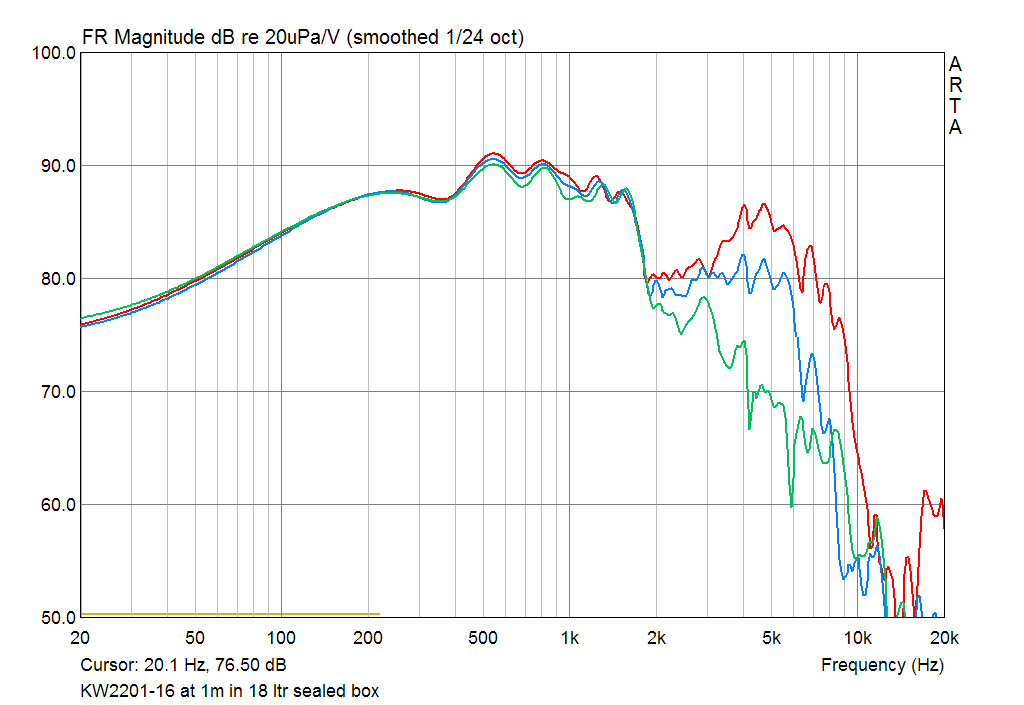

Frequency response at 1m with 2.83 V input RED - on axis, BLUE - 15 º off axis, GREEN - 30 º off axis

The second, third and fourth harmonic curves measured at 2.83V and 8V input RMS.

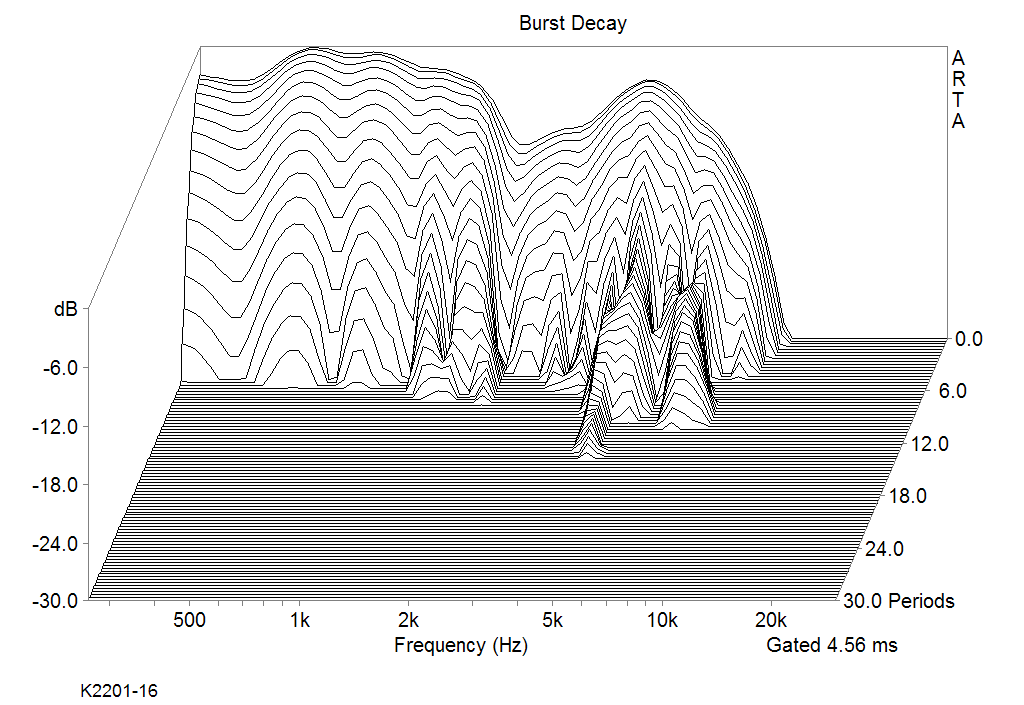

Burst decay response, measured at 1m on axis

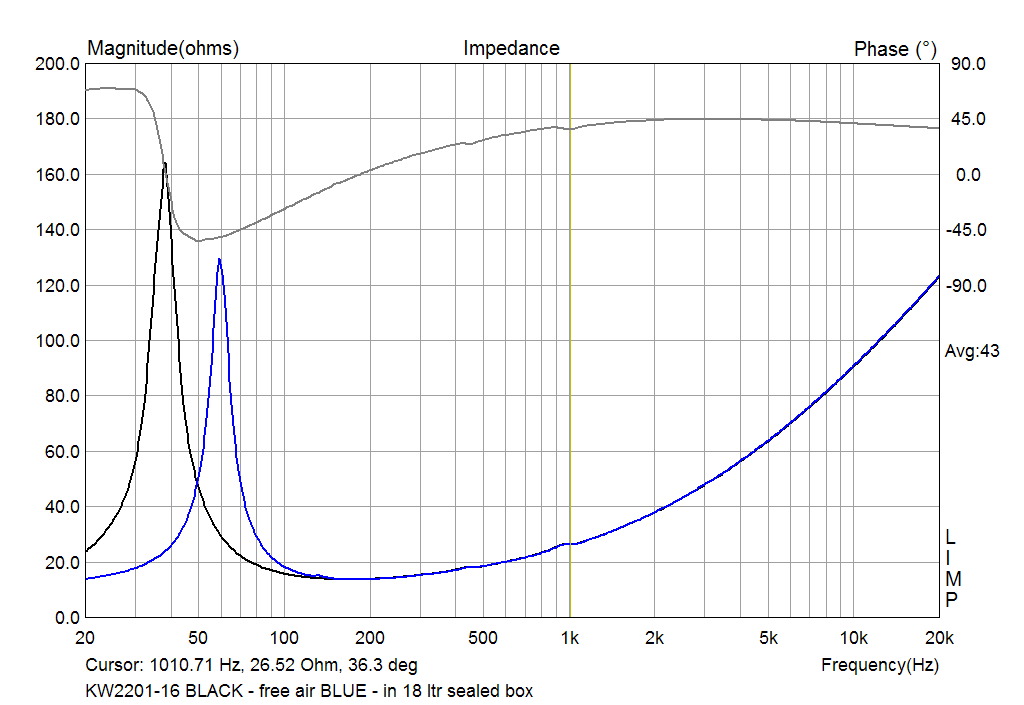

The impedance curve in 18 ltr sealed box

Conclusion

I does not happen very often that the result exceeds the

expectations concerning frequency response of a new developed

unit. Although this speaker was designed strictly as

low-frequency driver, it can be used up to 1800 Hz, which make

it suitable for two-way construction systems using the proper

tweeter.

The construction the KW2201-16 was designed for, is a compact

(30 ltr. per unit) bassreflex.